|

|

|

|

|

|

|

|

PLANETARY MIXER 100L(EXPERIMENTAL TYPE) |

PLANETARY MIXER 300L(PLC) |

|

|

|

|

|

PLANETARY MIXER 10L(HIGH SPEED TYPE) |

PLANETARY MIXER 75L(PIG TAILS TYPE) |

|

|

|

|

|

|

|

|

PLANETARY MIXER 5L(EXPERIMENTAL TYPE) |

|

|

|

|

|

|

PLANETARY MIXER 50L(HIGH SPEED TYPE) |

|

|

|

|

|

|

● MIXING VISCOSITY

It is possible mixing the various lines from low to high viscosity.

● THE APPLIED VISCOSITY(CP).

10,000 cp ~ 5,000,000 cp

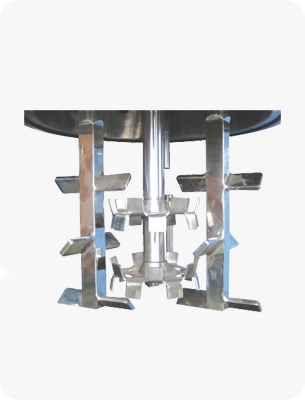

● DISPERSION IMPELLER

You can work efficiently due to moving the impeller (a style of cart wheel)in tank.

● TANK

The tank set up replaceable system and can be substituted reasonably the spare tank.

● STIRRED MIXED

Impeller type 2 or 3 in the tank to move the wheel can be used in machining precision products. Efficient mixing, blending, so the time can be shortened significanely.

● MACHINE CLEARING

The impeller can be separated from the revolving axis in case of clearing and emergency and also in case of clearing it is a good safety to be made by the style of separation tank.

● VACUUM DEFORAMING

Vacuum deforaming capability is unsurpassed. |

|

|

|

|

|

|

|

|

|

|

PLANETARY MIXER 1100L(HIGH SPEED TYPE) |

|

|

|

|

|

|

PLANETARY MIXER 750L(HIGH SPEED TYPE) |

PLANETARY MIXER 5L(INTEGRATED TYPE) |

|

|

|

|

|

PLANETARY MIXER 5L(RING TYPE) |

|

|

|

|

|

|

|

PLANETARY MIXER 200L(CAPACITOR INSTALLATION TYPE) |

|

|

|

|

|

PLANETARY MIXER 80L(RING TYPE) |

PLANETARY MIXER 5L(EXPERIMENTAL TYPE) |

|

|

|

|

|

PLANETARY MIXER 5L(EXPERIMENTAL TYPE) |

PLANETARY MIXER 5L(SQUARE TYPE) |

|

|

|

|

|

PLANETARY MIXER 1100L(HIGH SPEED TYPE) |

|

|

|

|

|

|

|

|

|

|

|

|

PLANETARY MIXER 150L(HIGH SPEED TYPE) |

PLANETARY MIXER 10L(INTEGRATED TYPE) |

|

|

|

|

|

|

PLANETARY MIXER 10L(HIGH SPEED TYPE) |

|

|

|

|

|

PLANETARY 100L(HIGH SPEED TYPE) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

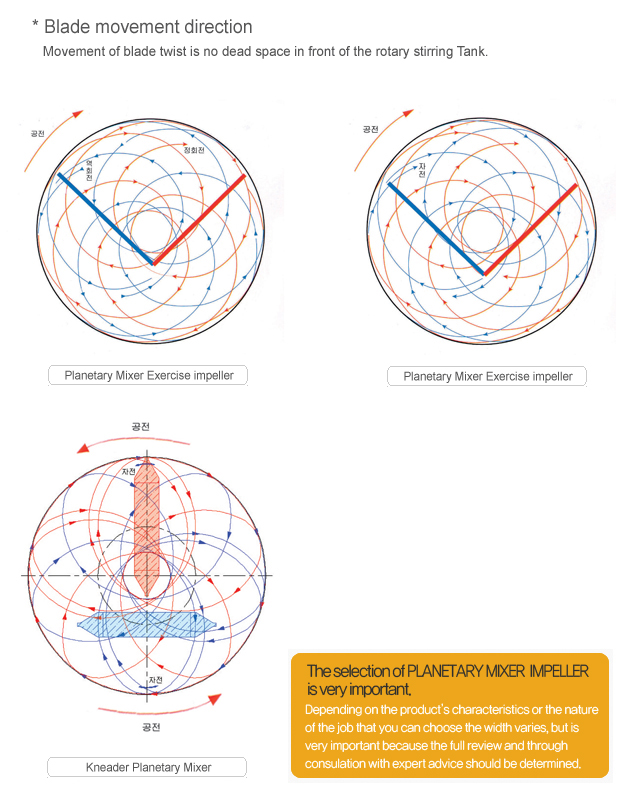

1. Impeller or a pair of two consists of three pair of rotation and revolution is made at the same time as the rotation.

2. Viscosity of the products have the patience to a single type of mixer impeller, you stand a raw material while tangled in the impeller rotation type mixer. Planetary mixer type two axis while moving the materials phenomena and the split is done repeatedly, because the symptoms appropriately raw materials are mixed at high speed.

3. Planetary mixer with the impeller and the mixing tank and narrow spacing(2m/m-6m/m) because the raw materials move as you push the scraper attachment eliminates the need for a separate mixer is not the extra empty space.

4. Mixing tnak, like the exchange can use multiple products vary depending on the type of change and can work.

5. Mixing tank and the impeller can be separated because of the convenient and safe in the event of three is excellent.

6. Depending on the nature of the product viscosity or triple double jacket and jacket to work with the installation of the heating unit is used and the cooling water can also be used.

7. Removing the tank after completing work with the product formulation is more efficient when working with a separate package.

8. Vacuum mixing upon completion or in progress with excellent defoaming capablilities and features, particularly working with high viscosity vacuum defoaming product changes from time to time to see through the glass it is convenient.

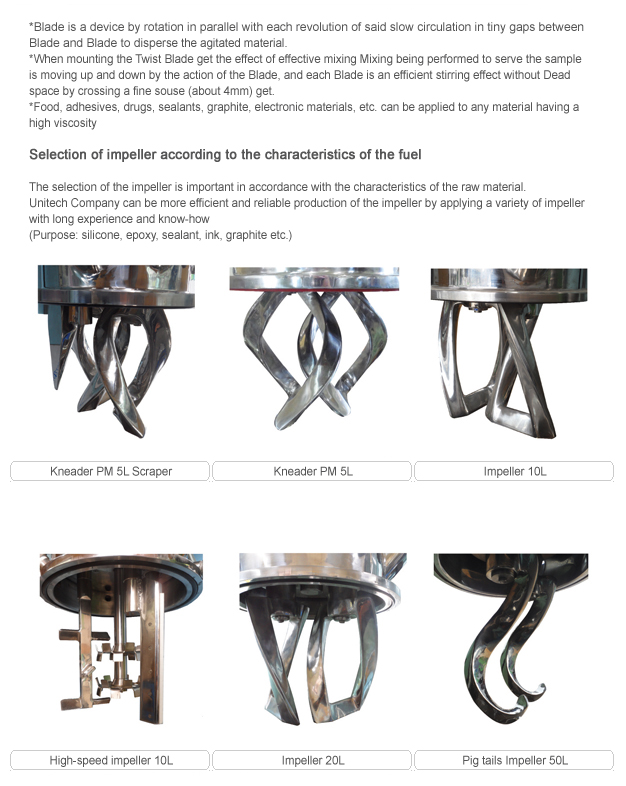

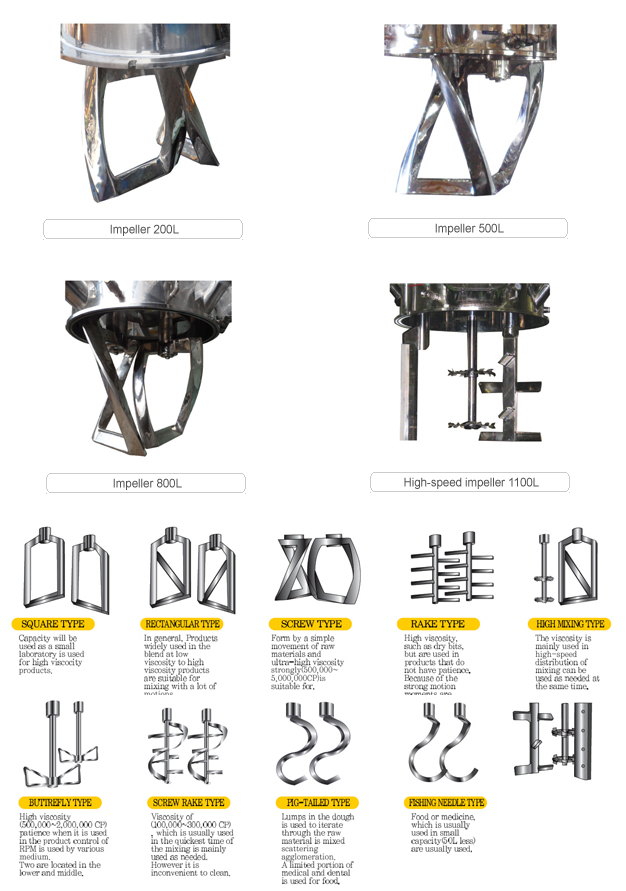

9. Impeller type, depending on the type of raw material properties and consist of several types. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|